ACT – Oil Fouling in Chiller Compressors

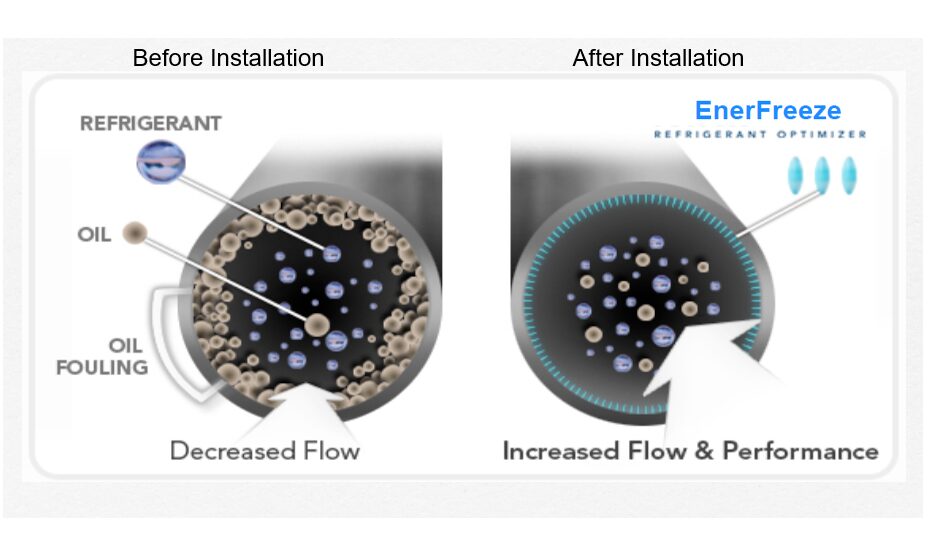

Chillers are widely used in industry and buildings. These machines contain two fluids - coolant and oil. Over a period of time the oil permeates into the coolant - a process which is known as “oil- fouling”. Since oil is more viscous, it has a higher co-efficient of friction. As the “oil-fouled” coolant circulates through the heat-exchanger, the oil sticks to the inside of the heat-exchanger tubes. This diminishes heat transfer by as much as 30% in less than 6 months, resulting in higher energy consumption, reduced life, increased maintenance, etc. Traditionally this has been remedied through the use of toxic and corrosive cleaners, which have to be used repeatedly because oil fouling cannot be prevented. The more appropriate solution is to prevent the oil from sticking to the insides of the heat-exchanger tubes, in the first place.

RTO (Refrigerant Treatment Optimizer) is a patented liquid which when injected into the oil, penetrates throughout the insides of the chiller and coats it with a Teflon-like layer which is only one molecule thick (nanotechnology) and dramatically lowers the coefficient of friction. Oil cannot stick to the inside of the chiller anymore. Specific procedures need to be followed to qualify for government grants.